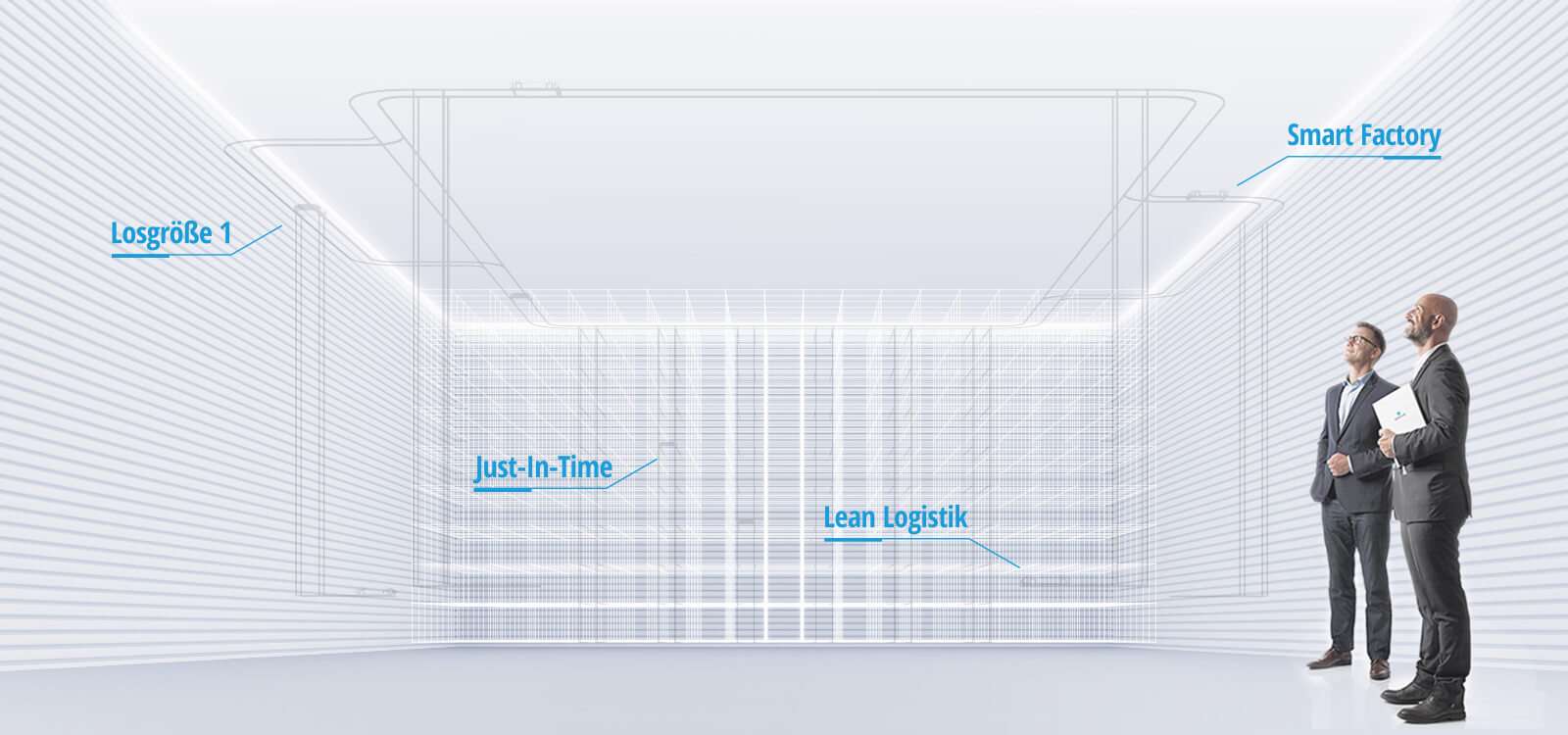

Warehouse and Production Logistics

Servus merges warehouse and production into a single unit. Autonomous transport robots by Servus convey your goods through the entire value chain. This makes seamless automation of your entire value chain from a single source a reality. Production and logistics are perfectly matched. Instead of isolated solutions, customers can keep track of the bigger picture at-a-glance. Industry 4.0 is no longer just a buzzword, but plays a key role in your company's success. With Servus, you can benefit from 15 years’ experience in merging warehousing and production.

Enabling Batch Size 1

From incoming goods, through warehousing, office, production, assembly and picking to outgoing goods, all areas of the company can be connected in an optimum flow process. Servus helps you implement a one-piece-flow and batch size 1 production.

Feedback in Real Time

Thanks to the seamless connection of warehousing and production, product and production data is available at any time and feedback in real time becomes a reality. Short feedback loops and faster error detection are the result, thus improving quality in your processes.

Seamlessly from Warehouse to Production

With Servus, small parts up to 50kg can be seamlessly transported from the warehouse to their desired destination within the company. The Servus modular assembly kit makes it possible to adapt warehousing, routes and the workplace to the available space and your processes.

Most of the Servus transport routes are overhead so that important assembly areas remain free for value-adding operations.

Customer Opinions