Initial Situation

- Existing production in a health care clean room.

- New building that required an intralogistics concept.

- Need for a fully automated, integrated logistics system that ensures the efficient in-house transport of aluminium trays and clean packs between production, warehouse, repackaging and palletising.

Customer Benefits

- Continuous material flow through warehouse and production.

- Customised, flexible, future-proof solution.

- Optimised energy consumption.

- Maximum process efficiency and safety.

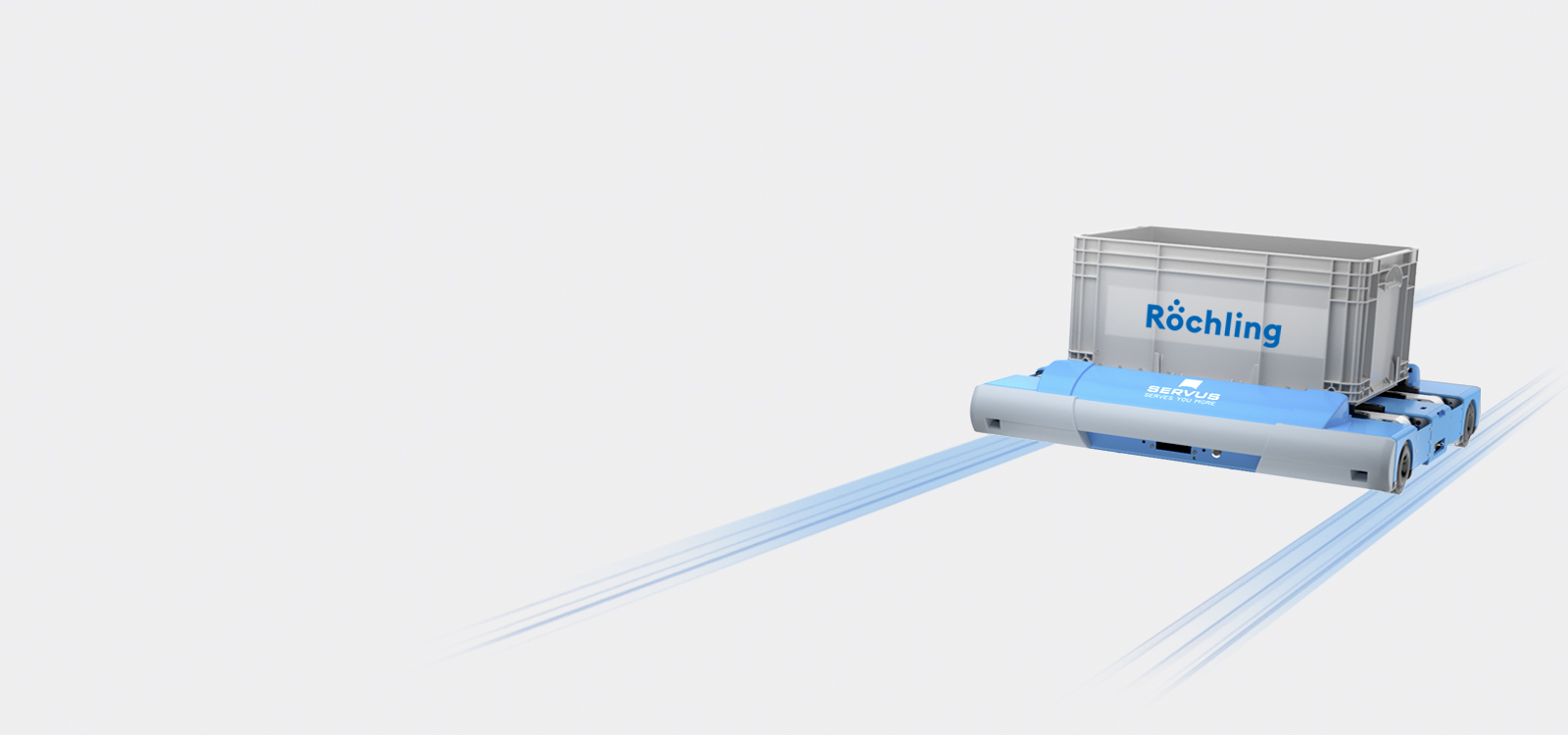

Servus in Action at Röchling Medical

Servus Intralogistics fully automates the internal material flow in the clean room at Röchling Medical since 2021. To meet the requirements of the cleanroom categories, a special airlock system has been integrated. In addition, the Servus system promotes the value-added activities of the employees and connects the transport of goods from the cleanrooms across floors.

Röchling Medical

The Röchling Group, which has been in existence for almost 200 years, develops and produces individual plastic solutions. As part of the group of companies, Röchling Medical specialises, among other things, in pharmaceutical primary packaging solutions, components and delivery systems for various pharmaceutical forms of application. As part of a new building and the associated comprehensive modernisation, the redesign of intralogistics was also on the agenda at Röchling's Neuhaus site - with the active support of Servus Intralogistics.

Thanks to our collaborative workshops, we were able to develop the best solution for us.