Initial Situation

- Many manual, time-consuming transport tasks

- Material storage for the assembly line supply directly in production

- Long routes – numerous manually operated interim storage facilities

- Hereditary structures with numerous areas and halls

- Complexity of supplying material to assembly machines

Customer Benefits

- Minimising manual transport tasks

- Constant access to 100% of all articles

- Eliminating search times

- Fully automated supply to assembly machines

- Just-in-time ordering of articles for dispatch leading to space savings in the dispatch area

- Additional space savings due to relocating the routes to the ceiling

- Copy of the solution for a second location

- “Breathing” production buffer can be optimised at all times

- Reserve capacities in the central AKL for future growth

- Clear-cut definition and clean-up of all processes in the course of introducing Servus including new warehouse management software

- Reducing work-in-progress stock.

Servus in Action at Rosenberger

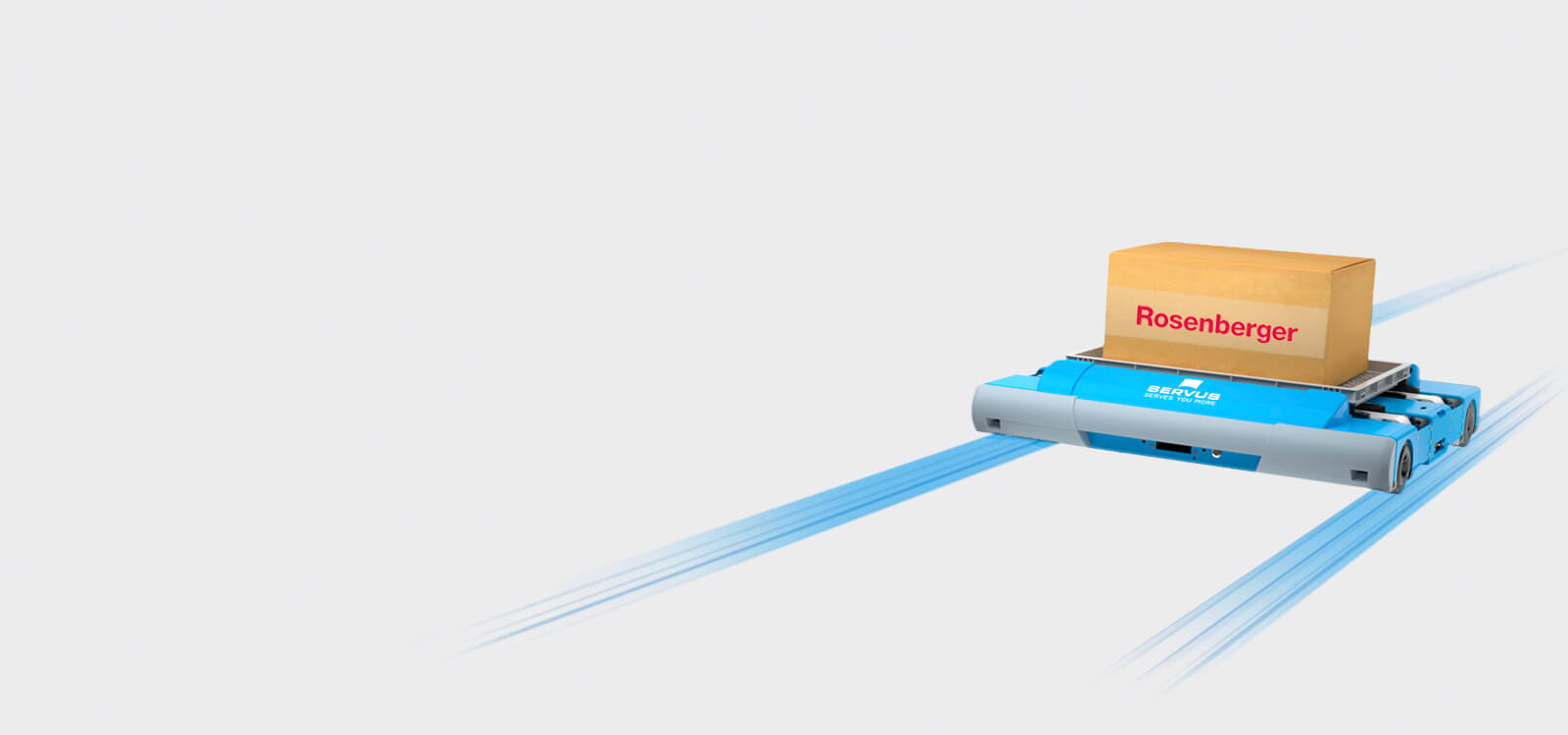

Servus handles the transport and storage of all small parts at Rosenberger. The transport robots move autonomously through the halls on “overhead routes”. If necessary, the goods are collected and stored at the point of origin or the right volumes are supplied to the desired workplace or outbound goods area at the right time. Implemented extension levels: Connection to Building 24, connection to Electroplating, doubling of storage capacity

More information on the Servus system at Rosenberger in Fridolfing can be found in the Schelling Case Study.

Rosenberger Hochfrequenztechnik GmbH & Co. KG

For more than half a century, the name Rosenberger has been associated with state-of-the-art technology, quality and creativity. The family-operated business is a leading manufacturer of high frequency and fibre optic technology connectivity solutions and employs approx. 7,500 staff worldwide. Its customers include well-known companies from the mobile communications and telecommunications, data processing, medical electronics, industrial metrology, automobile electronics and electromobility industries.

Rosenberger specifically invests in the development of new, high-quality products, state-of-the-art production processes and company processes, the conservation of resources and environmental protection. And above all, in its employees: Their professional ability and motivation are the future of the company.

In Servus, we have found an innovative intralogistics system. Servus extends the goods-to-the-worker principle. The goods are delivered directly to the assembly robot or the assembly line. In Servus, we have found a flexible system that works efficiently in line with lean principles. Thanks to the creativity of Servus and the project team, we have developed and launched completely new options and perspectives in logistics for the future.”