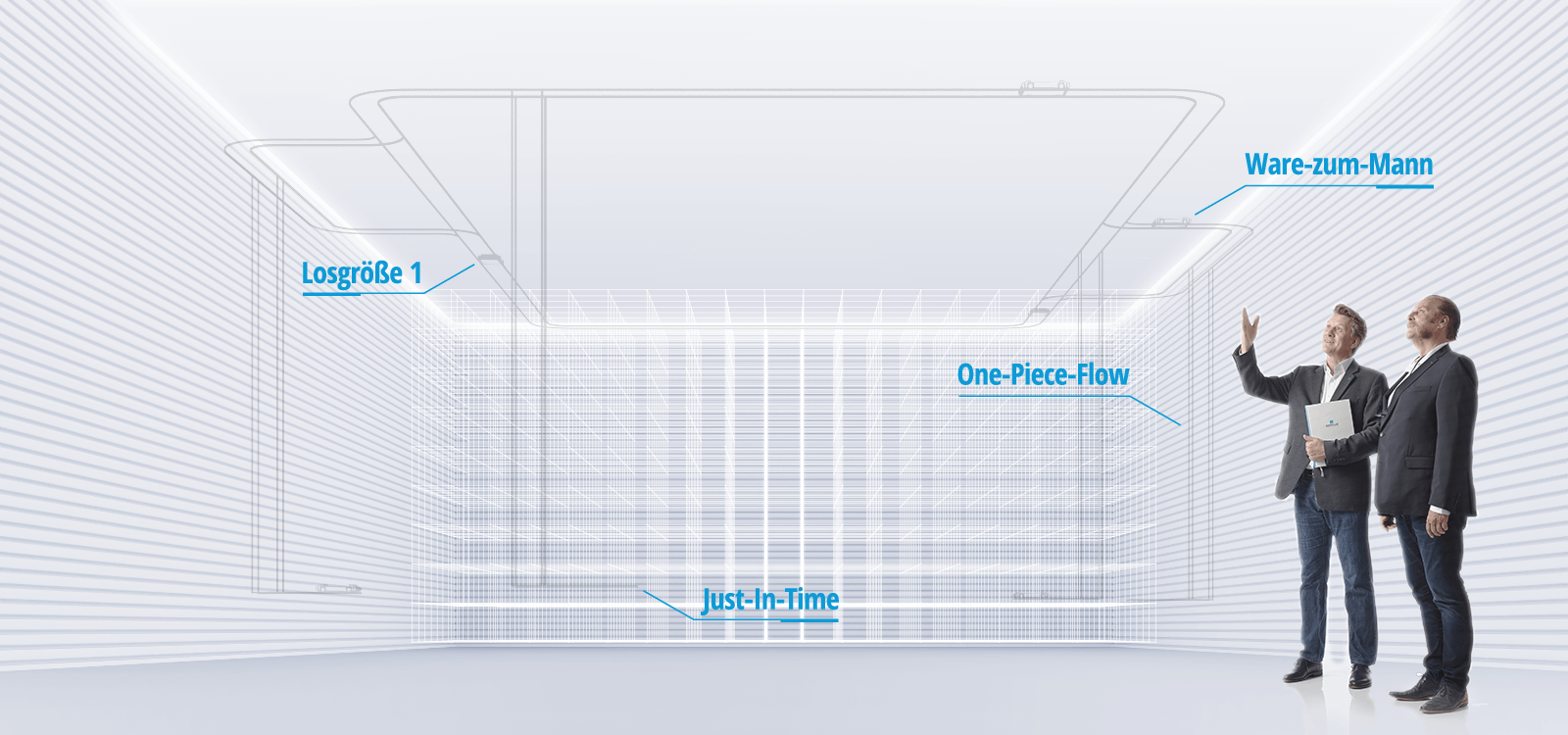

Lean Logistics for Your Production

We do not want to automate wastefulness, we want to eliminate waste. Lean production needs equally efficient logistics. Servus improves the material flow, reduces intermediate storage and on-site stock, thus freeing up space on the production lines. Servus ensures automated material transport along the entire value chain.

Simple Integration of All Processes

The simple integration of storage and removal stations, stations, assembly and picking stations, or breathing buffers make delivery and collection of goods possible at any location in the company. Manual and fully automated working stations are thus integrated into the flow process.

Intermediate Buffering

Servus buffers partial orders in a simple way, and then transfers the finished order to outbound goods. Servus can buffer semi-finished articles and feed them to the next production step at the correct time, and in the correct quantity.

Eliminating Waste

Search times are a thing of the past, because a constantly automated material flow with Servus enables product and production data feedback in real time. This improves the quality of the processes along the entire value chain. Errors in the production are virtually eliminated, and their consequences reduced to a minimum.

Lean Logistics in Production

While other means of transport block paths and critical floor-space, Servus transport robots travel overhead on the ceiling in order to save space. Servus only takes material down to working height at the location where it is actually needed.

In addition to manual workstations, production machines can also be directly integrated.

Customer Opinions