Warehouse Management and Picking

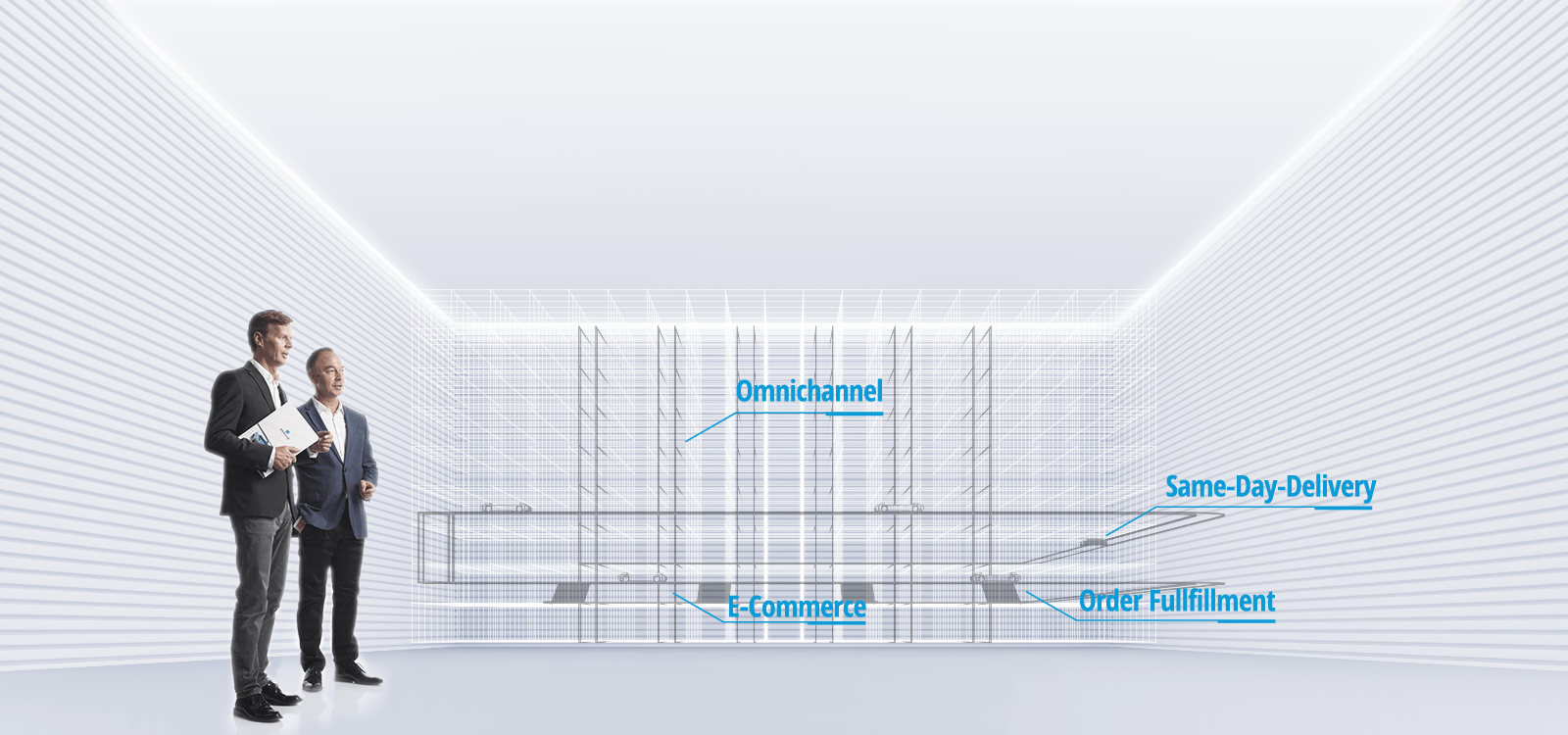

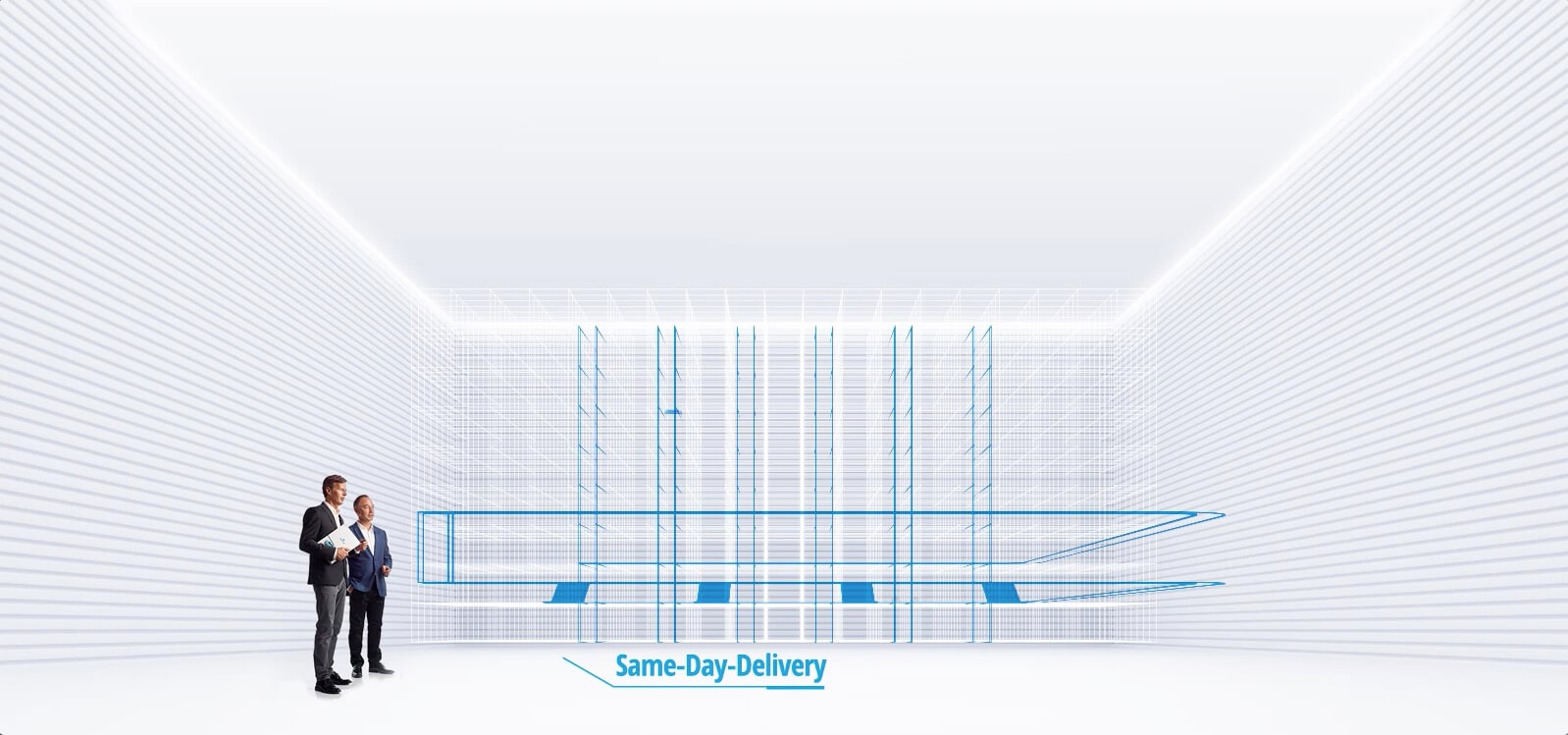

Automated small parts stores (ASRS) by Servus are always tuned to the customer’s needs. Whether for slow movers or highly dynamic storage and removal, whether single or double-depth storage. In addition, the Servus ASRS is fully integrated into the flow process, as the Servus transport robots simply leave the warehouse and supply the picking stations directly.

Picking and Packing

Like the layout of the entire system, the picking stations are custom-made. Pick-by-Scan, Pick-by-Light, Pick-to-Light, Pick-by-Vision, two-stage picking or Multi-Order-Picking are implemented according to the customer’s wishes. The Servus picking station determines the desired picking process.

SERVUS Warehouse Management (WMS)

Servus offers you a single source option for your entire warehousing logistics. Servus does not just take care of the hardware implementation of your warehouse (AKL and pallet store), but also ensures efficient warehouse management with our proprietary warehouse management software, the Servus Warehouse Management System (WMS).

Outstanding Efficiency of Servus Warehouses

Servus transport robots are not restricted to a single level as a result, Servus requires significantly fewer vehicles to manage a warehouse. The warehouse is seamlessly connected to the Servus picking stations.

The route can also be used as a store, since storage slots can be installed on the left and right along the route. This makes the system even more flexible.

A local picking station including intermediate buffer storage make provisioning for assembly even more efficient.

Customer Opinions: SERVUS Warehouse Management and Picking